Selecting the right PDR equipment is vital for achieving superior results in vehicle collision and auto frame repair. Consider tool compatibility with specific work requirements and damage types, such as impact guns with adjustable settings. High-quality, ergonomically designed tools prevent fatigue, enhance precision and speed, leading to faster turnaround times and satisfied customers. The PDR industry offers diverse tools, from traditional hammers to modern digital technologies, catering to various collision repair needs. When evaluating PDR equipment, key performance indicators include repair time reduction, advanced precision technology, versatility, and durability for long-term efficiency.

In the world of automotive detailing, Professional Detailing (PDR) stands out as a game-changer. To ensure optimal results, selecting the right PDR equipment is paramount. This article guides you through the essential aspects to look for in quality PDR tools, focusing on performance, durability, safety, and versatility. From understanding tool functionalities to evaluating key performance indicators, high-quality construction, and ergonomic designs, these factors will help maximize efficiency across various surface types.

- Choosing the Right PDR Tools for Optimal Performance

- – Understanding different types of PDR tools and their unique functionalities

- – Key performance indicators to consider when evaluating PDR equipment

Choosing the Right PDR Tools for Optimal Performance

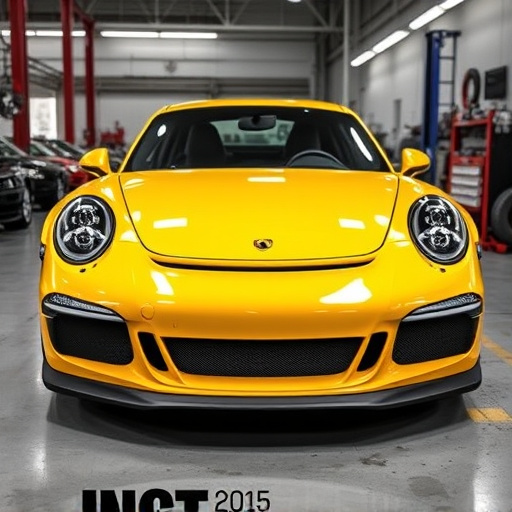

When it comes to PDR equipment, selecting the ideal tools is paramount for achieving top-notch results in vehicle collision repair and auto frame repair. The right set of tools can significantly enhance efficiency and accuracy during the tire services process. Consider factors such as tool compatibility with your specific work requirements and the types of damage you typically encounter. For instance, choosing impact guns with adjustable settings allows for versatile use in various scenarios, from minor dent removal to more complex auto body repairs.

Moreover, investing in high-quality PDR tools that are ergonomically designed can prevent fatigue during prolonged use, ensuring precision and consistency. Look for features like anti-vibration handles and lightweight designs, which not only improve comfort but also enable technicians to work with greater control and speed. This attention to detail can lead to faster turnaround times and happier customers in the competitive world of vehicle repair services.

– Understanding different types of PDR tools and their unique functionalities

The world of Professional Detail Restoration (PDR) equipment offers a wide array of tools, each designed to cater to specific needs in the collision repair shop or collision center. From hammer-based methods to advanced digital technologies, understanding these tools and their unique applications is key to achieving top-notch car restoration results.

One of the most common PDR tools is the paintless dent repair (PDR) hammer, used for gently removing dents from a vehicle’s body panel without damaging the paint job. On the other end of the spectrum, electronic PDR machines employ digital technology and specialized sensors to precisely locate and remove dents, offering greater control and consistency in the collision center environment. These tools are essential for achieving seamless car restoration results, ensuring that each dent is removed evenly and effectively.

– Key performance indicators to consider when evaluating PDR equipment

When evaluating PDR equipment, several key performance indicators (KPIs) are essential to ensure top-quality repairs for vehicle dent repair, auto frame repair, and vehicle paint repair. First and foremost, consider the tool’s effectiveness in reducing repair time. Efficient PDR equipment should streamline the process, allowing technicians to handle more jobs without compromising accuracy or quality. Additionally, look for tools with advanced technology that enhance precision, such as digital sensors and smart algorithms, which can detect and correct minor imperfections accurately.

Another critical KPI is the versatility of the equipment. High-quality PDR tools should be adaptable to various dent repair scenarios, from shallow dents to deep creases, ensuring they are suitable for different vehicle types and damage levels. Moreover, the durability and reliability of the equipment are vital, as they directly impact operational efficiency and cost-effectiveness in the long run. Invest in PDR tools that are built to last and have a proven track record in professional auto body shops.

When selecting PDR equipment, understanding the specific needs of your work and evaluating tools based on key performance indicators is essential. By considering the unique functionalities of different types and focusing on factors like durability, efficiency, and user-friendliness, you can ensure optimal performance and high-quality results. Investing in the right PDR equipment will not only streamline your processes but also enhance customer satisfaction.