Paintless dent removal (PDR) is a cutting-edge, non-invasive auto collision repair technique that uses specialized PDR equipment like dent pullers and tap sensors to gently manipulate metal surfaces, including aluminum panels, to remove dents without damaging the original factory finish or structural integrity. PDR is cost-effective, efficient, and preferred for its ability to preserve vehicle aesthetics and minimize extensive painting or complex repairs. Key PDR tools include specialized hammers and picks for precise manipulation, preserving lightweight, corrosion-resistant material finishes while enhancing panel aesthetics.

“Discover the revolutionary power of Paintless Dent Repair (PDR) for aluminum panel restoration. This innovative technique offers a non-invasive approach to dent removal, ideal for modern automotive care. In this article, we explore how PDR equipment, designed specifically for aluminum surfaces, enhances efficiency and quality. From understanding the PDR process to highlighting the benefits and considerations, we’ll guide you through the key aspects of using this advanced technology for effective dent repair.”

- Understanding PDR and Its Application on Aluminum Panels

- Key PDR Equipment for Efficient Dent Removal

- Benefits and Considerations for Using PDR on Aluminum Surfaces

Understanding PDR and Its Application on Aluminum Panels

Paintless dent removal (PDR) is a specialized technique within auto collision repair that has revolutionized vehicle bodywork restoration. Unlike traditional methods requiring auto body painting or extensive panel replacement, PDR uses advanced equipment to remove dents and dings from metal surfaces, including aluminum panels. This non-invasive approach is particularly beneficial for vehicles with delicate or hard-to-reach areas, as it preserves the original factory finish and structural integrity of the vehicle.

PDR equipment leverages the latest technology to gently manipulate the exterior of a vehicle. Specialized tools, such as dent pullers and tap sensors, are used to apply precise force, allowing technicians to pop dents back into place without leaving visible evidence or causing further damage. This method is not only efficient but also cost-effective, making it a preferred choice for auto collision repair, ensuring vehicles look like new while minimizing the need for extensive auto body painting or complex repairs in vehicle bodywork.

Key PDR Equipment for Efficient Dent Removal

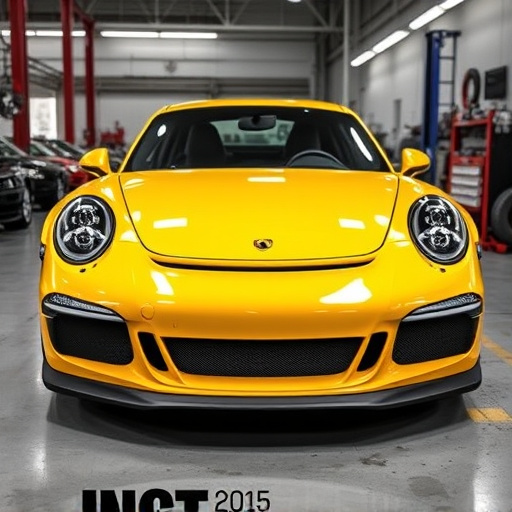

For efficient dent removal on aluminum panels, Professional Dent Repair (PDR) equipment is essential. Key tools include a variety of PDR hammers and picks designed to target different sizes and shapes of dents. These specialized instruments allow for precise manipulation, ensuring minimal damage to the car paint services while effectively restoring the panel to its original condition.

In any vehicle body shop or collision repair center, a robust set of PDR equipment is non-negotiable. The process leverages these tools’ ability to gently work around the dent’s perimeter, lifting and smoothing the metal without leaving visible marks. This not only enhances the aesthetics of the panel but also maintains the overall quality and integrity of the vehicle body, making it a preferred method in top-tier collision repair centers.

Benefits and Considerations for Using PDR on Aluminum Surfaces

Using PDR (Paintless Dent Repair) equipment for dent removal on aluminum panels offers several significant advantages. Aluminum is a lightweight and corrosion-resistant material commonly used in modern car bodywork, making it ideal for both performance and environmental sustainability. PDR techniques allow for non-invasive repairs, preserving the original factory finish and enhancing the aesthetic appeal of the vehicle without the need for auto body painting or extensive rework.

When considering PDR for aluminum surfaces, several factors come into play. The right PDR equipment is crucial for achieving precise results; specialized tools designed for aluminum can navigate complex panel contours more effectively. Additionally, proper training ensures that technicians apply the correct techniques to avoid marring the delicate metal. This method not only benefits car owners seeking efficient auto maintenance but also contributes to a more eco-friendly approach by reducing waste from traditional auto body painting processes and minimizing downtime related to bodywork repairs.

PDR (Paintless Dent Repair) has emerged as a game-changer in the automotive industry, offering efficient and cost-effective solutions for dent removal. When applied to aluminum panels, PDR not only restores the vehicle’s aesthetics but also preserves its value. By utilizing specialized PDR equipment, technicians can achieve precise results, making it an ideal choice for both professional body shops and DIY enthusiasts. The benefits are clear: faster repair times, minimal paint damage, and cost savings. With the right tools and techniques, PDR equipment allows for seamless dent removal on aluminum surfaces, ensuring a smooth and lustrous finish that meets the highest standards of automotive care.