PDR (Plastic Damage Repair) equipment has transformed vehicle restoration by providing cost-effective solutions for body damage repair, preserving paintwork and paneling. When upgrading your workshop, consider vehicle types, staff expertise, and specific needs to choose the right PDR tools, ensuring enhanced capabilities and customer satisfaction. Integrating new equipment should minimize disruption to existing workflows; plan tool placement, provide training, and ensure a smooth transition for optimal efficiency and improved service quality.

Looking to transform your workshop? Upgrading with new PDR (Paintless Dent Repair) equipment can revolutionize your car care game. This article guides you through the process, from understanding the benefits of advanced PDR tools to selecting the perfect fit for your needs. Learn how integrating new PDR equipment can streamline your workflow and enhance your services. Discover the latest innovations and take your workshop to the next level with efficient, high-quality PDR solutions.

- Understanding PDR Equipment and Its Benefits

- Selecting the Right PDR Tools for Your Workshop

- Integrating New PDR Equipment into Your Workflow Effortlessly

Understanding PDR Equipment and Its Benefits

PDR equipment refers to a range of specialized tools designed for Plastic Damage Repair, a process that restores damaged vehicles back to their pre-incident condition. This advanced technique has transformed vehicle repair services by offering cost-effective solutions for car damage repair and vehicle bodywork restoration. By employing PDR methods, technicians can effectively remove dents, scratches, and other types of surface imperfections without damaging the underlying paintwork or paneling.

One of the key benefits of PDR equipment is its versatility. These tools are capable of handling various types of vehicle damage, from minor dings and creases to more significant collisions. Using specialized PDR machines, such as hydraulic extraction tools, mallet sets, and air bag systems, technicians can precisely manipulate damaged areas, applying pressure in calculated manners to pop out dents or reshape bent panels. This meticulous approach ensures that the vehicle’s original factory finish is preserved, resulting in a visually seamless repair that matches the car’s overall aesthetics.

Selecting the Right PDR Tools for Your Workshop

When upgrading your workshop with new PDR (Paintless Dent Repair) equipment, selecting the right tools is paramount. The ideal PDR kit should align with the scope and volume of auto detailing or auto body services your shop typically handles. Consider factors like the size and type of vehicles commonly brought in for repair, as well as the level of expertise among your staff. For instance, a comprehensive PDR system suitable for professional auto repair services might include a variety of tools like daubers, tampers, and pullers to handle various dent removal tasks efficiently.

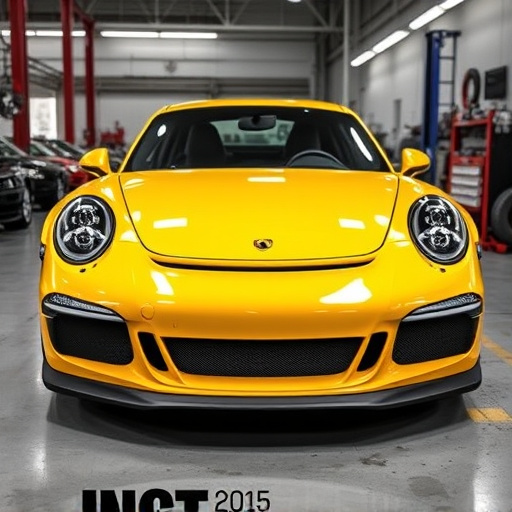

Additionally, think about the specific needs of your shop and target customers. If you specialize in high-end auto detailing, investing in top-tier PDR equipment that offers precision and versatility could be beneficial. Conversely, for a smaller operation focusing primarily on routine auto repair services, a more affordable yet effective kit might suffice. Remember, the right PDR tools can significantly enhance your workshop’s capabilities and customer satisfaction levels.

Integrating New PDR Equipment into Your Workflow Effortlessly

Integrating new PDR equipment into your workshop shouldn’t disrupt your existing workflow; instead, it should streamline and enhance it. Start by identifying the specific areas where the new tools can make the most impact. For instance, if you specialize in car scratch repair, invest in advanced PDR machinery designed for fine detail work. This way, you can dedicate each tool to its optimal use, ensuring maximum efficiency. A well-planned layout and clear training on the equipment will allow your team to adapt swiftly, minimizing downtime during the transition.

Remember, the best PDR equipment is the one that fits seamlessly into your auto repair services or auto collision center’s routine. This means considering not just the tools themselves but also how they integrate with your current inventory and workforce skills. By doing so, you’ll find that upgrading your workshop becomes a catalyst for improvement, elevating the quality of your car scratch repair and other auto-related services.

Upgrading your workshop with new PDR equipment can significantly enhance efficiency, improve repair outcomes, and better serve your customers. By understanding the benefits of PDR technology, carefully selecting the right tools for your needs, and seamlessly integrating them into your existing workflow, you can transform your workshop into a modern, competitive space. Investing in top-tier PDR equipment is a strategic move that pays dividends in both quality and profitability.